ISI Demolition was recently interviewed by The National Demolition Association for a feature article in the DEMOLITION Magazine. The content below was originally featured in their Q4 2024 issue of DEMOLITION Magazine:

For fans of Florida State University, Doak Campbell Stadium is more than just a place to watch football– it’s a symbol of tradition, pride and the electric atmosphere of game day. But as the demands of modern sports continue to grow, so does the need for facilities that can deliver a top-tier fan experience. That’s where NDA member ISI Demolition stepped in, taking on the task of dismantling parts of this iconic venue to make way for a new era of stadium enhancements.

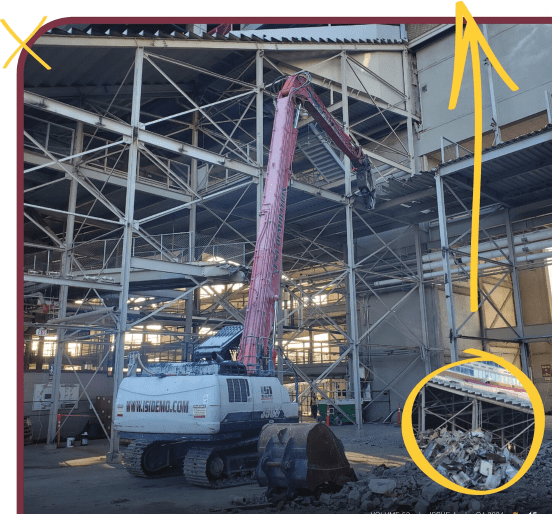

The project was no ordinary demolition. It was a carefully choreographed operation that demanded precision, coordination and a clear vision of the future. From high-reach excavators tearing down steel structures to the methodical removal of concrete foundations, every phase was a testament to ISI Demolition’s expertise and ingenuity.

“The demolition of the west grandstands and upcoming south endzone areas at Florida State University’s stadium was ordered to make way for new stadium upgrades,” says Blake Sheldon, project manager for ISI Demolition.

“These upgrades include new club and climate-controlled areas, upgraded chair back seating, and expanded food and beverage offerings.”

Now, with the west grandstands upcoming south endzone areas cleared, Doak Campbell Stadium is set for a major transformation, featuring new amenities that promise to redefine the fan experience. Here’s how ISI demolition raised the bar from what’s possible in stadium renovation.

“ISI Demolition was chosen through competitive bidding, backed by our extensive experience with previous stadium projects involving similar demolition scope.”

STRATEGIC SELECTION AND PLANNING

ISI Demolition was selected through a competitive bidding process, a testament to the company’s extensive experience in handling complex demolition projects. “ISI Demolition was chosen through competitive bidding, backed by our extensive experience with previous stadium projects involving similar demolition scopes,” Sheldon says. The project began in December 2023, with the demolition of the concourse level as the initial phase. Structural demolition took place from January to February 2024, followed by slab and foundation removal, which continued into March 2024.

EQUIPMENT USED:

- LINK-BELT 80X3 SPIN ACE

- LINK-BELT 250X4

- LINK-BELT 350X4

- BOBCAT SKID STEERS

- TORCHING AND WELDING EQUIPMENT

- SIMS CRANE

UNIQUE CHALLENGES: WORKING ALONGSIDE AN ACTIVE CAMPUS

One of the most significant challenges ISI Demolition faced was working around the University Center Building C, which remained operational through out the demolition. “This required meticulous planning and continuous monitoring to ensure that demolition activities did not disrupt the daily activities of the university or compromise the safety of students and staff,” Sheldon says. ISI Demolition implemented noise and vibration controls and established safety barriers to protect pedestrians and campus traffic, ensuring minimal disruptions to campus life.

The demolition was further complicated by the structural interdependences of the stadium with the adjacent buildings. “It required a carefully coordinated effort with the steel contractor to ensure that temporary bracing was installed in the timely and effective manner,” Sheldon says.

STEP-BY-STEP EXECUTION: A METHODICAL APPROACH

The demolition process unfolded in several carefully orchestrated phases:

Preparation and Enabling Work:

“The process began with essential preparation work, where our team chipped out pockets in the concrete of an adjacent building to facilitate the installation of new structural steel,” Sheldon says.

Clearing the Concourse Level:

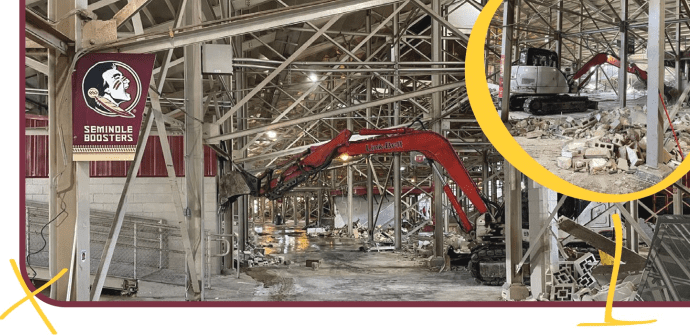

ISI Demolition removed nonstructural elements such as concession stands, signage, bleachers and bathrooms. This step allowed for a safer and more efficient workspace for the heavy equipment used in later stages.

Major Structural Demolition:

The team then moved to the structural phase, carefully dismantling steel seating structures. Heavy machinery, including high-reach excavators and cranes, was used to handle these tasks. “Our approach was to work methodically from one end to the other, coordinating closely with the steel contractor who installed temporary bracing along the adjacent building,” Sheldon says.

Below-Grade Demolition:

After the above-ground work, the team tackled the below-grade demolition, removing concrete foundations and piles. “This involved digging out and removing all the concrete foundations and piles, some at varying depths, using excavators,” Sheldon says. “This stage was particularly challenging due to the depth and amount of material that needed to be removed.”

Shoring and Partial Column Removal:

“On the north and south sides of the west grandstands, our engineers designed and installed in house shoring solutions. This allowed for the partial removal of existing steel columns and the installation of new permanent steel beams,” Sheldon says.

Post-Demolition and Site Cleanup:

Once the structural work was done, ISI Demolition focused on sorting debris for recycling and ensuring the site was clear of hazardous materials.

Preparation for Future Upgrades:

“The final phase of our involvement set the stage for upcoming architectural demolition and upgrades that were scheduled post the 2024 football season,” Sheldon says.

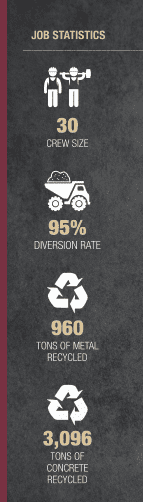

A COMMITMENT TO SUSTAINABILITY

ISI Demolition’s commitment to sustainability was a major highlight of the project. Achieving a 5% diversion rate, the team recycled 960 tons of metal and 3,096 tons of concrete. By carefully sorting materials, ISI Demolition minimized the environmental impact of the demolition, underlining its commitment to responsible practices.

OVERCOMING CHALLENGES WITH PRECISION AND COORDINATION

Working around an active campus building required ISI Demolition to implement rigorous safety protocols, including noise and vibration controls. “Managing the demolition activities near the University Center Building C, which remained operational throughout the project, required meticulous planning and continuous monitoring,” Sheldon says.

The successful coordination of multiple crews and contractors was critical to keeping the project on track. “The sequential teardown process demanded height precision and synchronization between multiple crews to prevent any structural instability,” he says.

DEFINING SUCCESS: SAFETY, EFFICIENCY AND ADAPTABILITY

Reflecting on the project, Sheldon emphasizes ISI Demolition’s dedication to safety and flexibility. “Success for us is defined not just by meeting project timelines and budgets but also by our flexibility in adapting to unexpected changes and challenges without compromising on safety,” Sheldon says. “Our team’s ability to adjust quickly to on-site demands and maintain a zero-injury record throughout the demolition speaks volumes about our commitment to safety and operation excellence.”

PREPARIND FOR THE FUTURE OF DOAK CAMPBELL STADIUM

As Doak Campbell Stadium prepares for its next chapter, ISI Demolition’s careful, strategic demolition has laid the groundwork for a seamless transformation. “The final phase of our involvement set the stage for upcoming architectural demolition and upgrades,” Sheldon says. ISI Demolition’s efforts have paved the way for enhancements that will improve the fan experience for years to come.

The Doak Campbell Stadium project illustrates how strategic planning, safety and sustainability can converge in complex demolition work. Through careful coordination, a methodical approach and a commitment to recycling, ISI Demolition has set a new standard for future projects, demonstrating that even the most intricate jobs can be executed responsibly and efficiently.

About ISI Demolition

ISI Demolition was founded in 1990 with a simple premise: Operate each day with the highest level of excellence. By following this guiding principle, it is no coincidence ISI Demolition consistently meets our clients’ goals for timeliness, efficiency, and safety. ISI Demolition works hand-in-hand with national, regional, and local contractors, developers, and commercial real-estate clients to understand project goals and devise individually tailored plans to meet those goals on time and on budget.

Just think of what you can accomplish when there are no obstacles!